Baffled Liquid Tanks: Unraveling The Solution To Efficient Fluid Storage! Click Now To Maximize Productivity!

Title: Baffled Liquid Tanks: Enhancing Efficiency and Safety

Introduction

Dear Readers,

2 Picture Gallery: Baffled Liquid Tanks: Unraveling The Solution To Efficient Fluid Storage! Click Now To Maximize Productivity!

Welcome to our informative article on baffled liquid tanks. In this article, we will explore the concept of baffled liquid tanks, their benefits, and their applications across various industries. Baffled liquid tanks are an innovative solution that enhances efficiency and safety in the transportation and storage of liquids. Join us as we delve into the world of baffled liquid tanks and discover how they revolutionize liquid management.

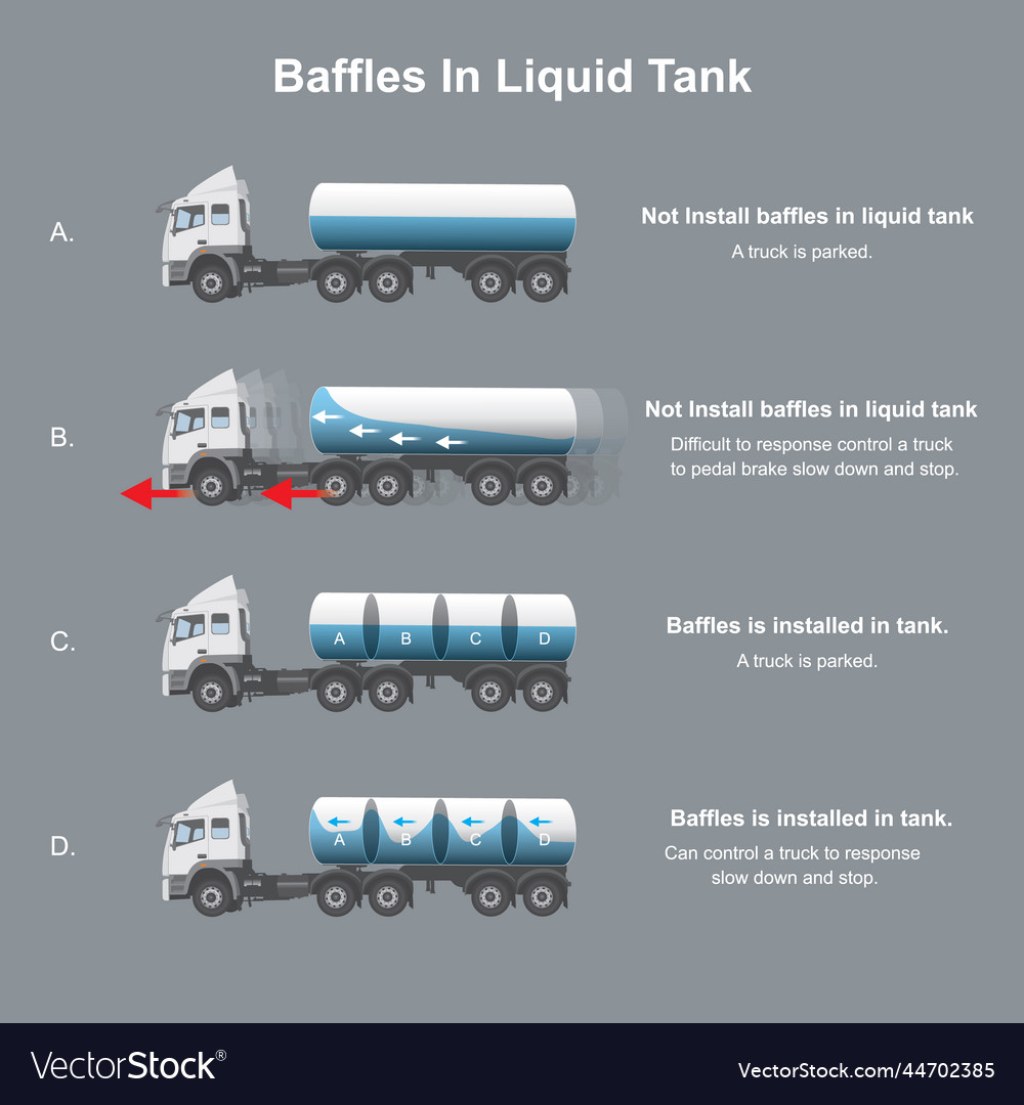

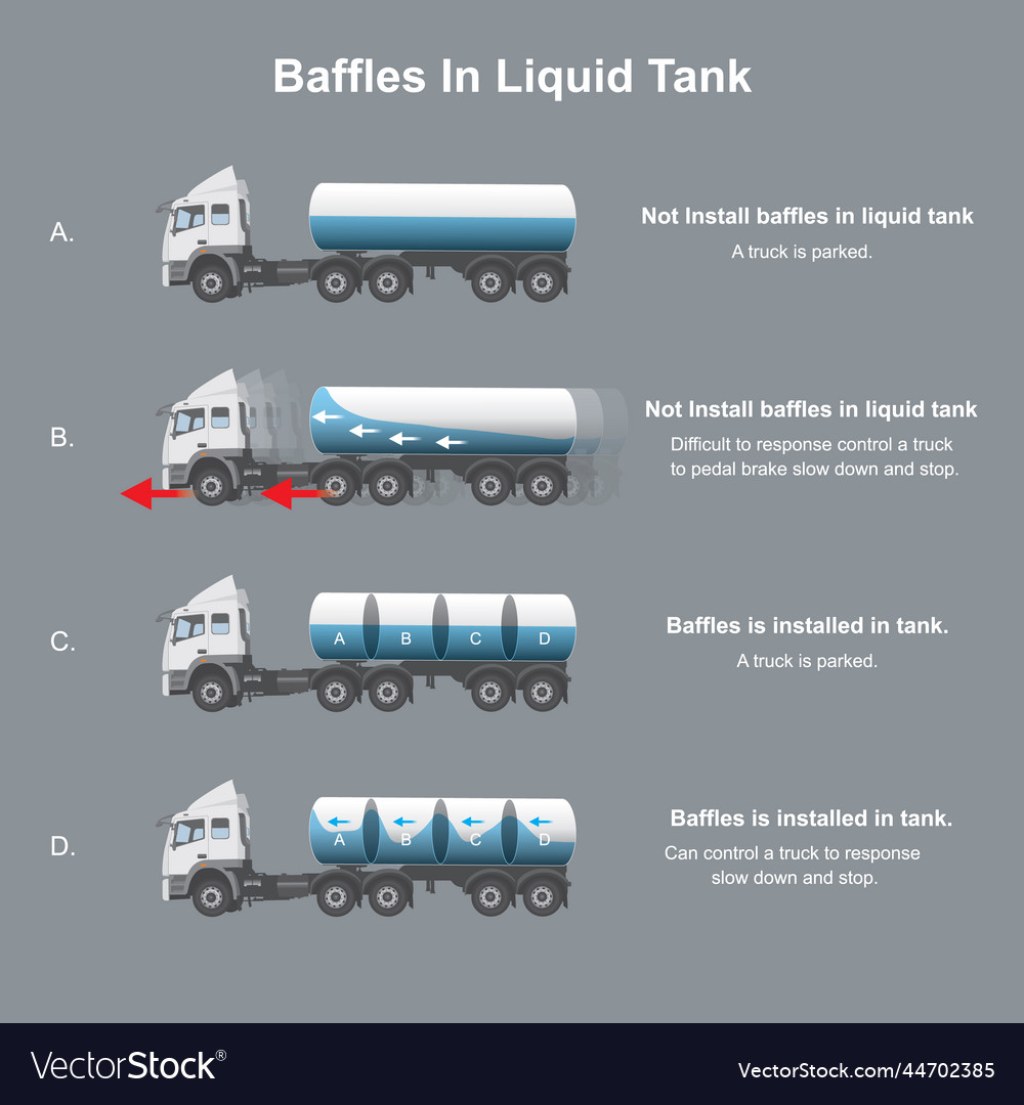

Image Source: vectorstock.com

In this article, we will cover everything you need to know about baffled liquid tanks. From their definition and components to their advantages, disadvantages, and frequently asked questions, we aim to provide you with a comprehensive understanding of this important technology.

Table: Baffled Liquid Tanks Information

Topic

Description

Definition

Introduction to baffled liquid tanks and their purpose.

Components

Explanation of the key components that make up baffled liquid tanks.

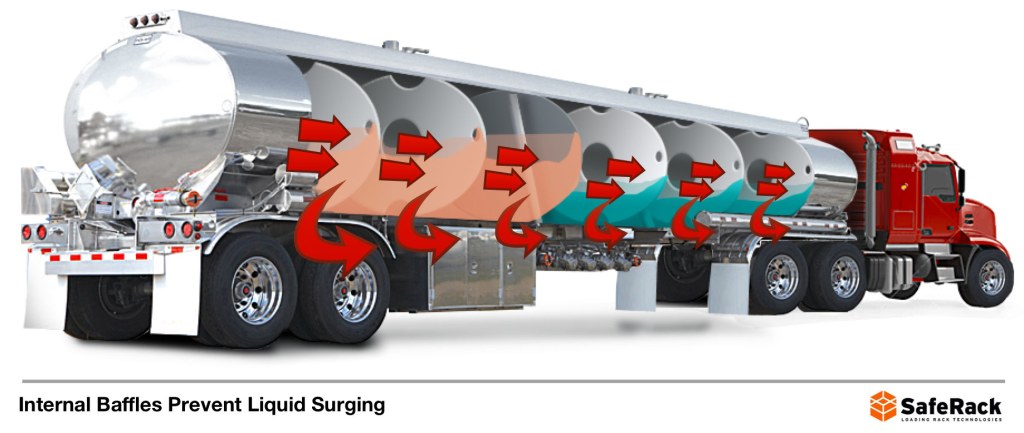

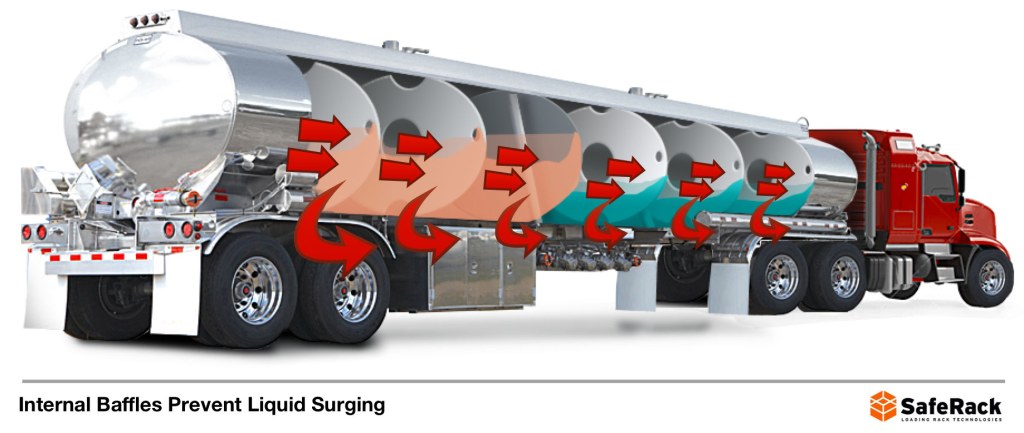

Image Source: saferack.com

Applications

Overview of the industries and scenarios where baffled liquid tanks are commonly used.

Benefits

Exploration of the advantages of utilizing baffled liquid tanks.

Disadvantages

An examination of the potential drawbacks and limitations of baffled liquid tanks.

FAQ

Answers to frequently asked questions regarding baffled liquid tanks.

Image Source: saferack.com

Conclusion

A summary of the key points discussed and a call to action for readers.

Final Remarks

Additional insights and a disclaimer regarding the information presented.

Definition

Baffled liquid tanks are specialized containers designed to store and transport liquids with improved stability and reduced sloshing. These tanks feature internal partitions, called baffles, which help control the movement of fluids within the tank. By restricting the liquid’s motion, baffles minimize sloshing and enhance the overall safety and efficiency of liquid transportation.

Components

Baffled liquid tanks consist of several key components that work together to ensure optimal performance. These components include:

1. Tank Body: The main structure of the tank that holds the liquid.

2. Baffles: Internal partitions that divide the tank into compartments.

3. Mounting Brackets: Secure the baffles within the tank.

4. Inlet and Outlet Ports: Openings for filling and draining the tank.

5. Ventilation System: Allows air to enter and exit the tank during liquid transfer.

6. Mounting System: Enables easy installation of the tank onto various vehicles or surfaces.

Applications

Baffled liquid tanks find applications in a wide range of industries, including:

1. Transportation: Baffled tanks are used in the transportation of liquids, such as fuel, chemicals, and food-grade substances, by road, rail, or sea.

2. Agriculture: These tanks are employed in agricultural settings for the storage and distribution of fertilizers, pesticides, and water for irrigation.

3. Oil and Gas: Baffled tanks play a crucial role in the oil and gas industry, facilitating the safe storage and transportation of various petroleum-based products.

4. Food and Beverage: They are utilized in the food and beverage industry to transport and store liquids, including juices, milk, and alcoholic beverages.

5. Construction: Baffled tanks are essential for construction projects, enabling the efficient transport and storage of water, cement, and other construction materials.

6. Emergency Services: Firefighters and emergency responders utilize baffled tanks to store and transport water for firefighting and disaster relief efforts.

7. Chemical Industry: Baffled tanks are employed in the chemical sector to safely handle and transport a wide range of chemicals.

Benefits

Enhanced Stability 🔥

Baffled liquid tanks significantly reduce liquid sloshing during transportation, ensuring enhanced stability and improved safety. This stability is especially critical when transporting hazardous or delicate liquids.

Increased Efficiency 🔝

The presence of baffles in these tanks prevents liquid surge, enabling faster and more efficient liquid transfer. This feature reduces transportation time and enhances overall productivity.

Minimized Contamination 🙄

Baffles in the tank prevent cross-contamination by dividing the liquid into separate compartments. This segregation ensures the integrity and quality of different liquids being transported.

Improved Fuel Efficiency 🚗

The controlled movement of liquid within baffled tanks reduces fuel consumption by minimizing the energy required to counteract sloshing. This results in improved fuel efficiency and cost savings.

Enhanced Safety 🛡

By reducing liquid sloshing, baffled liquid tanks minimize the risk of accidents, such as rollovers or spills, enhancing overall safety during transportation or storage.

Disadvantages

Reduced Capacity 💦

The presence of baffles in the tank decreases its overall liquid-holding capacity. This reduction in capacity may be a limitation for certain applications that require maximum volume.

Increased Weight 🔥

The addition of baffles and mounting brackets increases the weight of the tank, which can affect the payload capacity of vehicles and increase transportation costs.

Higher Cost 💲

Baffled liquid tanks are generally more expensive than standard tanks due to the added complexity of their design and the materials required for the baffles.

Cleaning Complexity 😦

The presence of baffles can make cleaning the tank more challenging, as the partitions may hinder access to certain areas, requiring specialized cleaning methods.

Application Limitations 🛈

While baffled tanks are suitable for many applications, certain liquids or specific transportation requirements may not be compatible with this type of tank. It is important to assess individual needs before selecting a baffled tank.

FAQ

Q: Are baffled liquid tanks suitable for storing and transporting corrosive chemicals?

A: Yes, baffled liquid tanks can be constructed with materials that are resistant to corrosion, making them suitable for storing and transporting corrosive chemicals safely.

Q: Can baffled tanks be customized to fit different vehicle sizes?

A: Yes, baffled tanks can be customized to fit various vehicle sizes and can be easily mounted for seamless integration.

Q: Can baffled liquid tanks be retrofitted into existing tankers or trucks?

A: Yes, baffled tanks can be retrofitted into existing tankers or trucks, provided they meet the necessary structural requirements.

Q: Are baffled tanks compliant with industry safety standards?

A: Yes, baffled tanks are manufactured to meet industry safety standards and regulations to ensure the safe transportation and storage of liquids.

Q: Can baffled liquid tanks be used for long-distance transportation?

A: Yes, baffled tanks are designed to withstand the demands of long-distance transportation, providing stability and safety during extended journeys.

Conclusion

In conclusion, baffled liquid tanks offer significant advantages in terms of stability, efficiency, and safety in the transportation and storage of liquids. Their internal partitions, or baffles, control the movement of fluids, reducing sloshing and enhancing overall performance. While they come with limitations such as reduced capacity and increased weight, their benefits outweigh these drawbacks in most scenarios.

We encourage you to explore the potential of baffled liquid tanks in your industry or application. Whether you’re in the transportation, agriculture, construction, or any other sector that deals with liquids, baffled tanks can revolutionize your liquid management processes.

Investing in baffled liquid tanks is a smart choice that can lead to increased efficiency, reduced costs, and improved safety. Take the leap into the world of baffled liquid tanks and experience the advantages firsthand.

Final Remarks

Dear Readers,

We hope this article has provided you with valuable insights into baffled liquid tanks and their role in enhancing efficiency and safety. It is important to note that while we strive to provide accurate and up-to-date information, the specific requirements and regulations may vary depending on your location and industry.

Before implementing baffled liquid tanks, we recommend consulting with industry experts and adhering to local regulations to ensure compliance and optimal performance.

Thank you for joining us on this journey to explore baffled liquid tanks. If you have any further questions or require additional information, please feel free to reach out to us. Cheers to improved liquid management with baffled tanks!

This post topic: Liquid