Unleash The Power Of Closed Loop Liquid Nitrogen Cooling System: Experience Unparalleled Cooling Efficiency And Take Action Today!

Closed Loop Liquid Nitrogen Cooling System: An Efficient Solution for Temperature Control

Introduction

Dear Readers,

3 Picture Gallery: Unleash The Power Of Closed Loop Liquid Nitrogen Cooling System: Experience Unparalleled Cooling Efficiency And Take Action Today!

Welcome to this informative article about closed loop liquid nitrogen cooling systems. In today’s fast-paced world, where technology is advancing at an unprecedented rate, the need for efficient temperature control in various industries has become crucial. This article aims to provide you with a comprehensive understanding of closed loop liquid nitrogen cooling systems and their benefits. So, let’s dive in and explore this fascinating technology further!

Overview of Closed Loop Liquid Nitrogen Cooling System

Image Source: pcmag.com

A closed loop liquid nitrogen cooling system is a state-of-the-art technology designed to regulate and maintain precise temperature levels in industrial processes. It operates on the principle of using liquid nitrogen as a coolant to remove excess heat generated during manufacturing operations, scientific experiments, or any other application requiring temperature control.

This system consists of a closed loop, where liquid nitrogen circulates through a network of pipes and heat exchangers, absorbing heat from the surroundings and dissipating it efficiently. It offers superior cooling performance, ensuring optimal operating conditions and enhancing the longevity and reliability of equipment.

What is a Closed Loop Liquid Nitrogen Cooling System? 🌡️

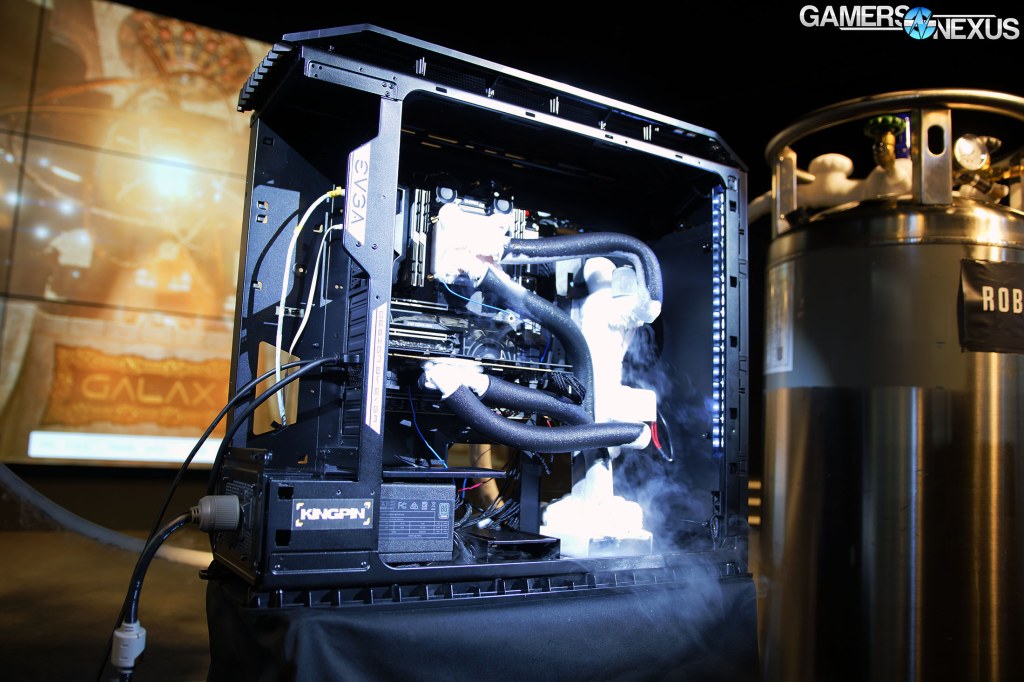

Image Source: gamersnexus.net

A closed loop liquid nitrogen cooling system is an innovative solution that utilizes the properties of liquid nitrogen to maintain precise temperature levels in various industrial applications. By circulating liquid nitrogen through a closed loop, excess heat can be effectively removed, allowing for efficient and reliable operation of equipment.

🔍 In this section, we will delve deeper into the working principles, components, and benefits of closed loop liquid nitrogen cooling systems.

Working Principles of a Closed Loop Liquid Nitrogen Cooling System

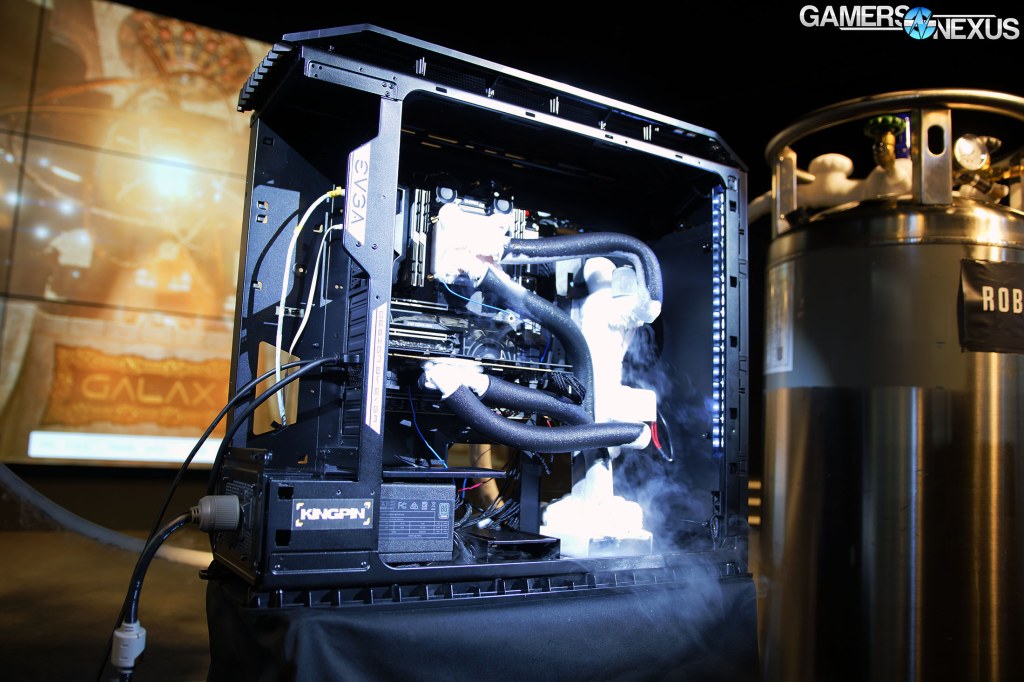

Image Source: gamersnexus.net

The working principles of a closed loop liquid nitrogen cooling system are based on the heat transfer properties of liquid nitrogen. When liquid nitrogen comes into contact with a heat source, it rapidly evaporates, absorbing heat from its surroundings. This phase change from liquid to gas allows for efficient heat removal.

By circulating the evaporated nitrogen gas through a loop, it can be cooled back into liquid form in a heat exchanger. This cooled liquid nitrogen is then recirculated to remove heat from the system, ensuring consistent temperature control.

Components of a Closed Loop Liquid Nitrogen Cooling System

A closed loop liquid nitrogen cooling system comprises several essential components:

Storage Tank: This is where the liquid nitrogen is stored before being circulated through the system.

Pump: The pump is responsible for circulating the liquid nitrogen throughout the loop.

Heat Exchanger: The heat exchanger facilitates the transfer of heat from the system to the liquid nitrogen, allowing for efficient cooling.

Control Unit: The control unit monitors and regulates the temperature of the liquid nitrogen to ensure optimal performance.

Cooling Equipment: This refers to the equipment or machinery that requires temperature control and is connected to the closed loop liquid nitrogen cooling system.

Benefits of Closed Loop Liquid Nitrogen Cooling System

The utilization of closed loop liquid nitrogen cooling systems offers several benefits:

🌡️ Precision Temperature Control: These systems can maintain precise temperature levels, ensuring optimal conditions for various industrial processes.

⏱️ Improved Efficiency: By effectively dissipating excess heat, closed loop liquid nitrogen cooling systems enhance the efficiency and performance of equipment.

💧 Reduced Water Consumption: Compared to traditional cooling methods, these systems require much less water for cooling, contributing to water conservation efforts.

🔇 Quiet Operation: Closed loop liquid nitrogen cooling systems operate silently, minimizing noise pollution in industrial settings.

💼 Cost Savings: By reducing energy consumption and minimizing equipment downtime, these systems can result in significant cost savings for industries.

Who Can Benefit from Closed Loop Liquid Nitrogen Cooling Systems? 🌍

Closed loop liquid nitrogen cooling systems have a wide range of applications across various industries. Some of the key beneficiaries include:

🏭 Manufacturing Industries: These systems are indispensable in industries that involve high-temperature processes, such as metalworking, plastics manufacturing, and semiconductor fabrication.

🔬 Laboratories and Research Facilities: Closed loop liquid nitrogen cooling systems are extensively used in scientific research to maintain precise temperatures during experiments.

🔥 Fire and Safety Services: These systems are employed in fire and safety services to cool down equipment and prevent overheating.

🌡️ Medical and Healthcare: Closed loop liquid nitrogen cooling systems play a vital role in medical and healthcare applications, including cryotherapy, cryosurgery, and cold storage of biological samples.

🔌 Electronics and IT: These systems are crucial in cooling electronic components and data centers, where temperature control is essential for maintaining optimal performance.

When to Implement Closed Loop Liquid Nitrogen Cooling Systems? ⏰

Implementing closed loop liquid nitrogen cooling systems can be beneficial in various scenarios:

⚙️ High-Temperature Processes: If your industry involves processes that generate high levels of heat, implementing a closed loop liquid nitrogen cooling system can help maintain optimal operating conditions.

🌡️ Precision Temperature Control: Industries requiring precise temperature control, such as laboratories, research facilities, and medical applications, can greatly benefit from these systems.

🔌 Electronics Cooling: To ensure the longevity and reliability of electronic components, especially in data centers, closed loop liquid nitrogen cooling systems are an ideal solution.

Where to Find Closed Loop Liquid Nitrogen Cooling Systems? 🌐

Closed loop liquid nitrogen cooling systems are offered by various reputable manufacturers and suppliers worldwide, specializing in temperature control solutions. These systems can be found through:

🌐 Online Supplier Websites

🏢 Industrial Equipment Distributors

📞 Direct Contact with Manufacturers

💼 Industry Trade Shows and Exhibitions

Why Choose Closed Loop Liquid Nitrogen Cooling Systems? ❓

Closed loop liquid nitrogen cooling systems offer numerous advantages over traditional cooling methods:

🌡️ Superior Cooling Performance: These systems provide efficient and effective cooling, surpassing the capabilities of conventional methods.

🔋 Energy Efficiency: By dissipating heat at the source, closed loop liquid nitrogen cooling systems reduce energy consumption and contribute to a greener environment.

🔇 Silent Operation: These systems operate silently, making them ideal for noise-sensitive environments.

💧 Water Conservation: Unlike traditional cooling methods, closed loop liquid nitrogen cooling systems require minimal water, contributing to water conservation efforts.

💼 Cost-Effectiveness: By improving equipment performance and minimizing downtime, these systems offer substantial cost savings in the long run.

How to Implement Closed Loop Liquid Nitrogen Cooling Systems? 🛠️

Implementing a closed loop liquid nitrogen cooling system involves the following steps:

1️⃣ Assessment: Evaluate your specific cooling requirements and identify the suitable closed loop liquid nitrogen cooling system for your application.

2️⃣ Design: Collaborate with experts to design a customized system that meets your unique needs and integrates seamlessly with your existing equipment.

3️⃣ Installation: Engage professional technicians to install the system correctly, ensuring optimal performance and safety.

4️⃣ Testing and Calibration: Thoroughly test and calibrate the system to ensure it functions according to specifications and provides accurate temperature control.

5️⃣ Maintenance and Monitoring: Establish a regular maintenance schedule to keep the system in optimal condition and monitor its performance to address any potential issues promptly.

Advantages and Disadvantages of Closed Loop Liquid Nitrogen Cooling Systems

Like any technology, closed loop liquid nitrogen cooling systems have their advantages and disadvantages:

Advantages:

🌡️ Superior Cooling Performance: These systems offer efficient and effective cooling, ensuring optimal operating conditions.

🔋 Energy Efficiency: By dissipating heat at the source, closed loop liquid nitrogen cooling systems reduce energy consumption.

🔇 Silent Operation: These systems operate silently, minimizing noise pollution in industrial settings.

💧 Reduced Water Consumption: Unlike traditional cooling methods, closed loop liquid nitrogen cooling systems require minimal water for cooling.

💼 Cost Savings: By improving equipment performance and minimizing downtime, these systems result in significant cost savings.

Disadvantages:

⚠️ Initial Investment: Implementing a closed loop liquid nitrogen cooling system may involve a significant upfront cost.

⚙️ Complex Installation: These systems require professional installation and expertise for optimal performance.

Frequently Asked Questions (FAQs) 📚

Here are some commonly asked questions about closed loop liquid nitrogen cooling systems:

1. What is the operating temperature range of closed loop liquid nitrogen cooling systems?

Closed loop liquid nitrogen cooling systems can operate within a wide temperature range, typically ranging from -150°C to +150°C.

2. Are closed loop liquid nitrogen cooling systems environmentally friendly?

Yes, closed loop liquid nitrogen cooling systems are environmentally friendly as they reduce energy consumption and minimize water usage compared to traditional cooling methods.

3. Can closed loop liquid nitrogen cooling systems be customized for specific industrial applications?

Absolutely! Closed loop liquid nitrogen cooling systems can be designed and customized to meet the specific temperature control requirements of various industrial applications.

4. How do closed loop liquid nitrogen cooling systems compare to air-based cooling systems?

Closed loop liquid nitrogen cooling systems offer superior cooling performance and energy efficiency compared to air-based cooling systems. They are particularly advantageous in high-temperature processes.

5. What safety measures should be considered when using closed loop liquid nitrogen cooling systems?

When using closed loop liquid nitrogen cooling systems, it is essential to follow proper safety protocols, including wearing appropriate personal protective equipment and ensuring proper ventilation in the facility.

Conclusion: Optimize Your Temperature Control with Closed Loop Liquid Nitrogen Cooling Systems

In conclusion, closed loop liquid nitrogen cooling systems provide an efficient and reliable solution for temperature control in various industries. With their precise temperature regulation, energy efficiency, and numerous other benefits, these systems have become indispensable in modern manufacturing processes, research laboratories, and other temperature-sensitive applications.

By implementing a closed loop liquid nitrogen cooling system, you can optimize your operations, enhance equipment performance, and contribute to a greener and more sustainable future.

Final Remarks

Dear Readers, we hope this article has provided you with valuable insights into the world of closed loop liquid nitrogen cooling systems. As with any technology, it is crucial to partner with reputable manufacturers and suppliers who can offer tailored solutions to meet your specific requirements. Remember to prioritize safety when working with liquid nitrogen and always follow proper handling procedures.

Thank you for joining us on this educational journey. Stay cool, stay efficient!

This post topic: Liquid