Revolutionary Liquid Additive Manufacturing: Unleashing Boundless Possibilities!

The Revolutionary Technology of Liquid Additive Manufacturing

Introduction

Dear Readers,

3 Picture Gallery: Revolutionary Liquid Additive Manufacturing: Unleashing Boundless Possibilities!

Welcome to an exciting journey into the world of liquid additive manufacturing. In this article, we will explore the innovative technology that is revolutionizing the manufacturing industry. From its inception to its applications and benefits, we will delve into every aspect of liquid additive manufacturing, also known as LAM.

Image Source: faps.fau.eu

So, grab a cup of coffee and join us as we unravel the mysteries behind this groundbreaking technology.

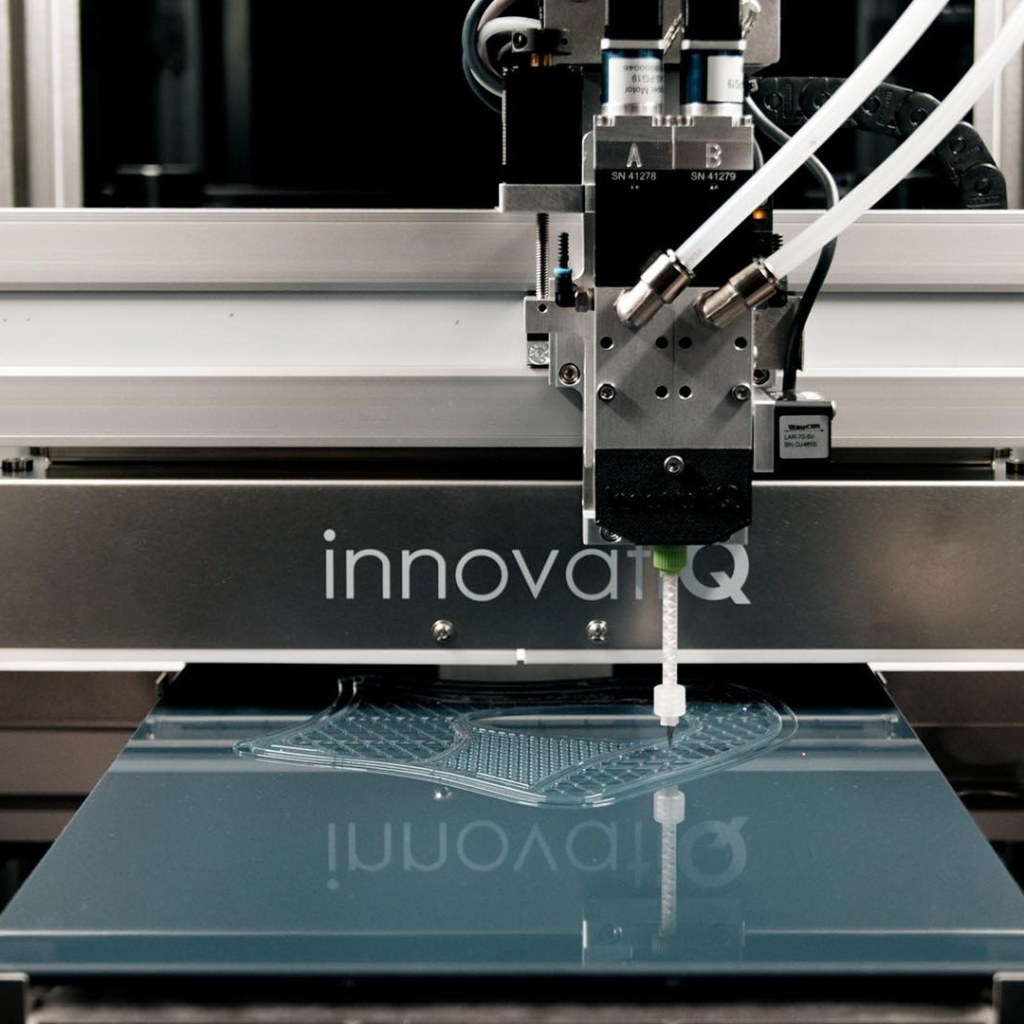

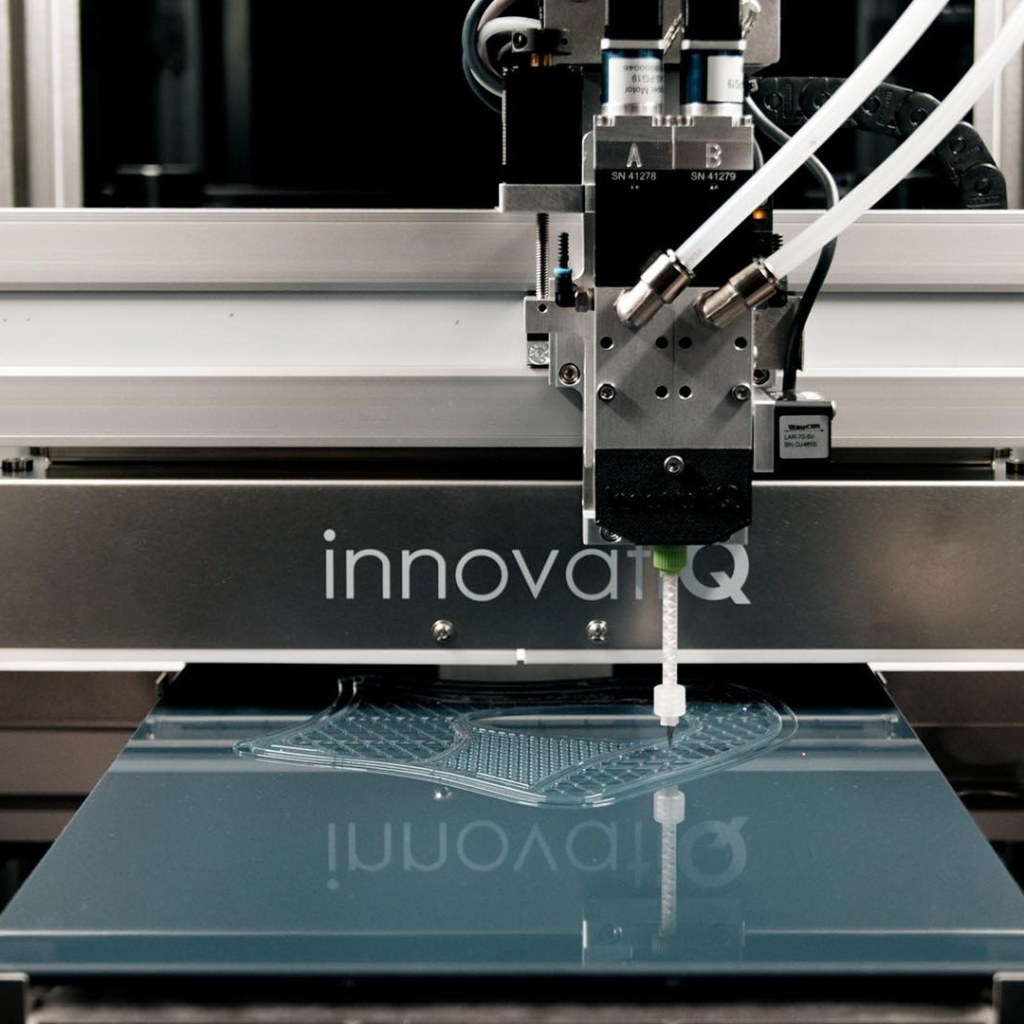

What is Liquid Additive Manufacturing? 🌟

Liquid additive manufacturing is a cutting-edge process that allows for the creation of complex three-dimensional objects using liquid materials. Unlike traditional manufacturing methods, which involve the removal of material to shape an object, LAM builds objects layer by layer, using a liquid resin or other material.

Image Source: innovatiq.com

This state-of-the-art technology has gained significant attention in recent years due to its ability to produce intricate designs with high precision and efficiency.

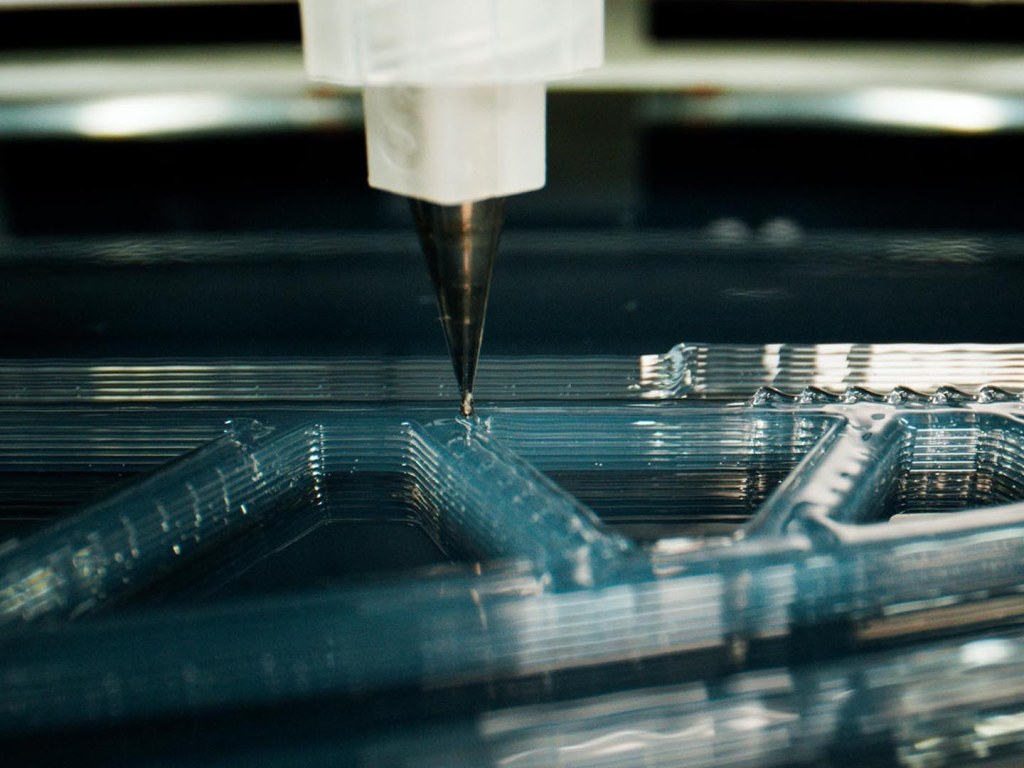

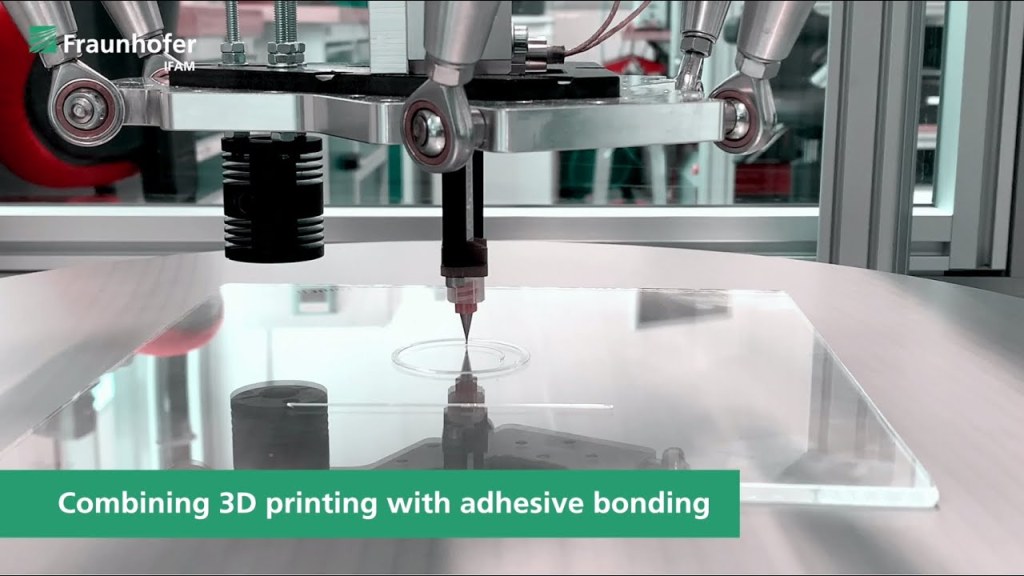

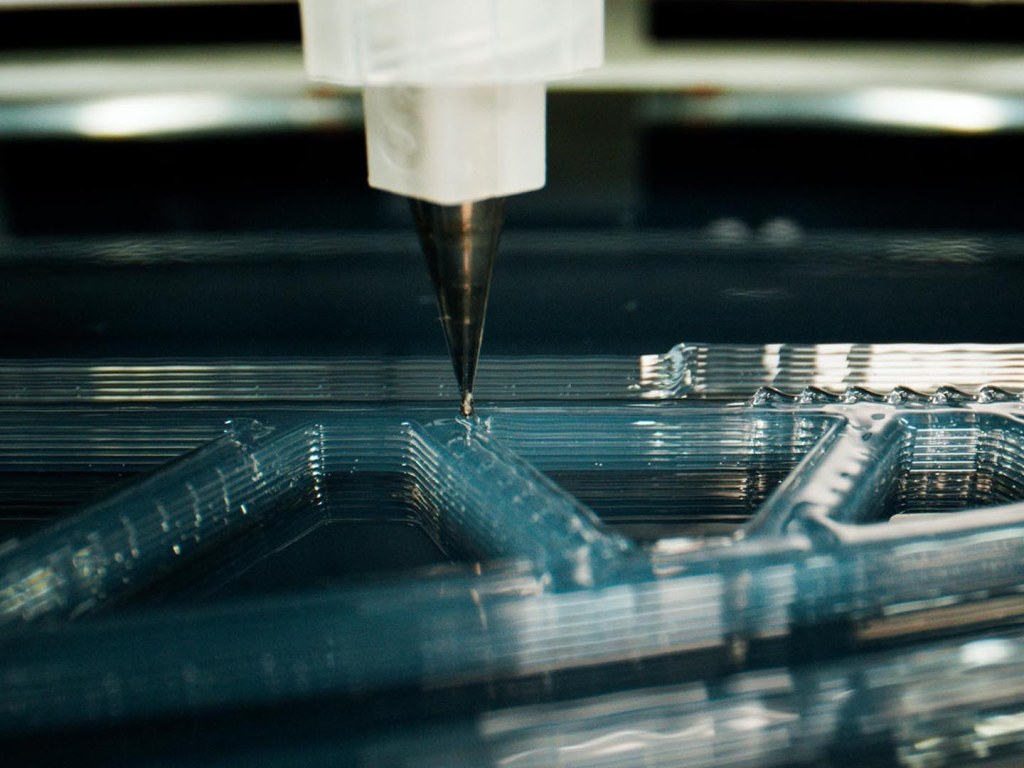

How Does Liquid Additive Manufacturing Work? 🤔

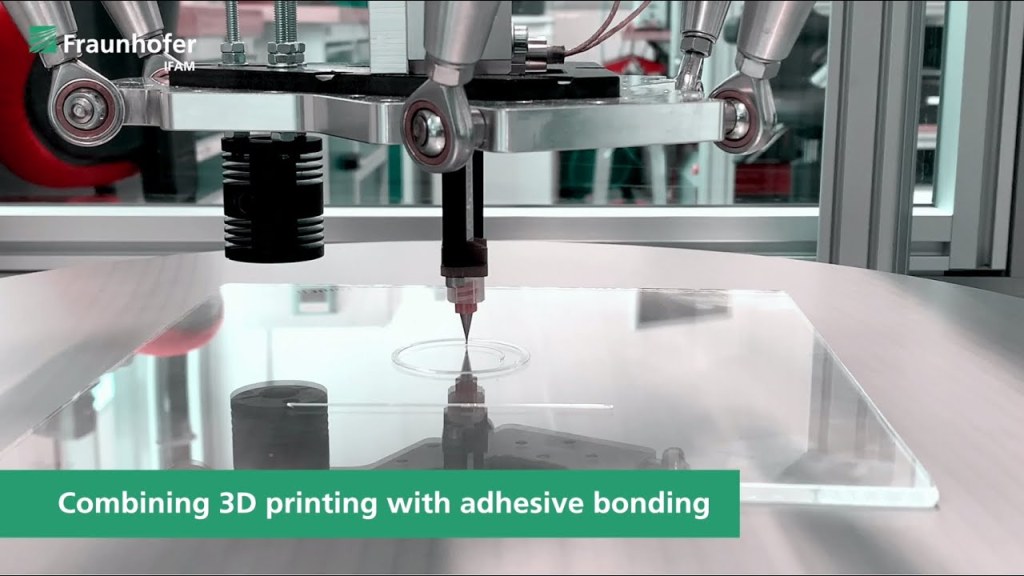

Liquid additive manufacturing begins with a digital model of the desired object. This model is then sliced into thin layers using specialized software. The liquid material, often a photopolymer resin, is then applied to a build platform. A high-precision nozzle deposits the liquid layer by layer, which is then cured or solidified using UV light.

Image Source: ytimg.com

This process is repeated until the entire object is built, resulting in a complete, three-dimensional product.

Who Uses Liquid Additive Manufacturing? 🔬

Liquid additive manufacturing has found applications in a wide range of industries, including aerospace, automotive, healthcare, and consumer goods. Engineers, designers, and manufacturers utilize this technology to create prototypes, functional parts, and even end-use products.

With its ability to produce complex geometries and lightweight structures, LAM has become an invaluable tool for industries that demand high-performance components.

When was Liquid Additive Manufacturing Invented? ⏳

The concept of additive manufacturing dates back to the 1980s. However, liquid additive manufacturing, in particular, has gained prominence in the last decade. Advancements in materials, software, and hardware have made LAM more accessible and cost-effective, driving its adoption in various industries.

Where is Liquid Additive Manufacturing Used? 🌍

Liquid additive manufacturing is used in manufacturing facilities and research laboratories worldwide. Countries like the United States, Germany, China, and Japan have been at the forefront of developing and implementing this technology.

From small-scale workshops to large-scale production facilities, LAM has made its mark in numerous locations across the globe.

Why Choose Liquid Additive Manufacturing? ✅

The advantages of liquid additive manufacturing are numerous. Firstly, it allows for the creation of highly complex and customized designs that were previously impossible with traditional manufacturing methods.

Additionally, LAM reduces material waste as it only uses the necessary amount of liquid material, making it a more sustainable option. It also enables faster production times, lower costs, and greater design flexibility.

However, like any technology, liquid additive manufacturing also comes with its own set of challenges and limitations that need to be considered.

The Pros and Cons of Liquid Additive Manufacturing

Advantages of Liquid Additive Manufacturing 🌟

1. Design Freedom: LAM allows for the creation of intricate and customized designs that were previously unachievable.

2. Time and Cost Efficiency: The layer-by-layer construction process reduces production times and material waste, resulting in cost savings.

3. Lightweight Structures: LAM enables the creation of lightweight components with high strength, ideal for applications in aerospace and automotive industries.

4. Minimal Post-Processing: Finished parts often require minimal post-processing, reducing the overall manufacturing time.

5. Iterative Prototyping: LAM enables rapid prototyping, allowing for quick iterations and design modifications.

Disadvantages of Liquid Additive Manufacturing ❌

1. Limited Material Options: The range of materials available for liquid additive manufacturing is still relatively limited compared to traditional manufacturing methods.

2. Surface Finish: Parts produced through LAM may require additional post-processing to achieve a desired surface finish.

3. Size Limitations: The size of the objects that can be produced using LAM is currently limited by the build volume of the machine.

4. Equipment Cost: The initial investment in liquid additive manufacturing equipment can be high, making it less accessible for small businesses.

5. Regulatory Challenges: As with any emerging technology, there may be regulatory hurdles and standards that need to be addressed.

Frequently Asked Questions (FAQs) 📚

1. Can liquid additive manufacturing be used for mass production?

Yes, liquid additive manufacturing can be utilized for small-scale production runs. However, for large-scale mass production, other manufacturing methods might be more suitable due to cost and time considerations.

2. Can liquid additive manufacturing create functional end-use parts?

Absolutely! Liquid additive manufacturing can produce functional end-use parts, especially in industries where complex geometries and lightweight structures are desired.

3. What are the limitations of liquid additive manufacturing?

Some limitations of liquid additive manufacturing include limited material options, surface finish requirements, size limitations, equipment costs, and regulatory challenges.

4. Is liquid additive manufacturing environmentally friendly?

Compared to traditional manufacturing processes, liquid additive manufacturing reduces material waste, making it a more sustainable option. However, it is important to consider the environmental impact of the materials used and the energy consumption of the equipment.

5. How can I implement liquid additive manufacturing in my business?

Implementing liquid additive manufacturing in your business requires careful planning, investment in equipment and training, and understanding the specific needs and applications relevant to your industry.

Conclusion

In conclusion, liquid additive manufacturing has emerged as a game-changing technology with vast potential. Its ability to create intricate designs, reduce costs, and accelerate production times has made it a valuable tool for various industries.

As the technology continues to evolve, we can expect even more advancements and applications in the future. So, embrace the future of manufacturing and explore the possibilities that liquid additive manufacturing has to offer.

Thank you for joining us on this journey, and we hope you found this article informative and inspiring. Now, it’s time for you to take action and explore the world of liquid additive manufacturing!

Final Remarks

Dear Friends,

Before we conclude, we would like to emphasize that the information provided in this article is based on the current state of technology and industry practices. It is important to stay updated with the latest developments and consult experts in the field before making any decisions or investments related to liquid additive manufacturing.

We strive to provide accurate and reliable information, but we cannot be held responsible for any actions taken based on the content of this article.

Remember, the future of manufacturing is bright, and liquid additive manufacturing is at the forefront of this revolution. Embrace the possibilities, explore the potential, and shape the future with this groundbreaking technology.

This post topic: Liquid