Revolutionary Liquid Level Control System: Optimize Your Operations With Our Cutting-Edge Solution!

Liquid Level Control System: Ensuring Efficient Management of Fluid Levels

Greetings, Readers! Today, we will delve into the world of liquid level control systems and explore how they play a crucial role in various industries. Whether it is monitoring water levels in a reservoir or ensuring precise measurements in chemical processes, liquid level control systems are an integral part of modern-day operations. In this article, we will provide a comprehensive overview of this technology, discussing its definition, functionality, advantages, and more. So, let’s dive right in!

Introduction

1. Defining Liquid Level Control System: 📚

3 Picture Gallery: Revolutionary Liquid Level Control System: Optimize Your Operations With Our Cutting-Edge Solution!

A liquid level control system is an automated mechanism designed to monitor and regulate fluid levels in tanks, reservoirs, and other containers. It employs a combination of sensors, actuators, and control algorithms to maintain the desired liquid level within a specified range. This system is widely used in industries such as oil and gas, chemical processing, water treatment, and manufacturing.

2. Components of a Liquid Level Control System: 🔧

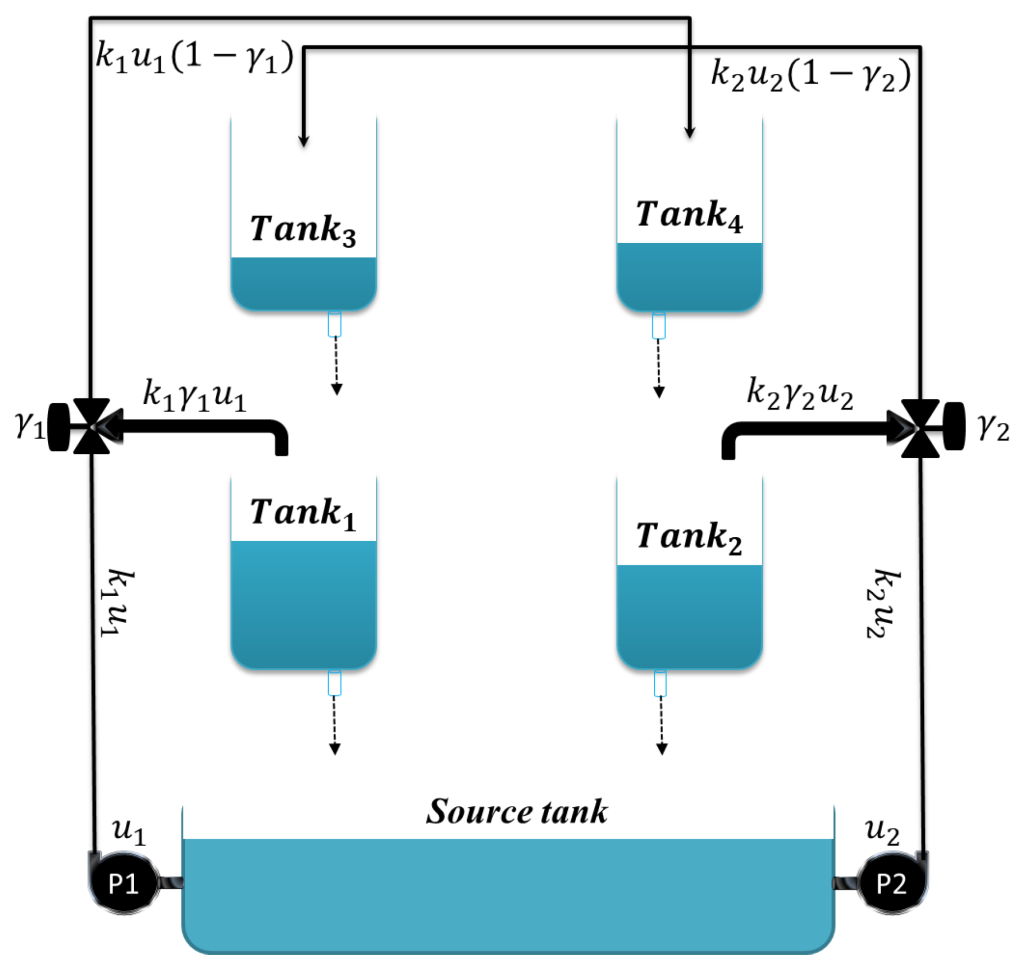

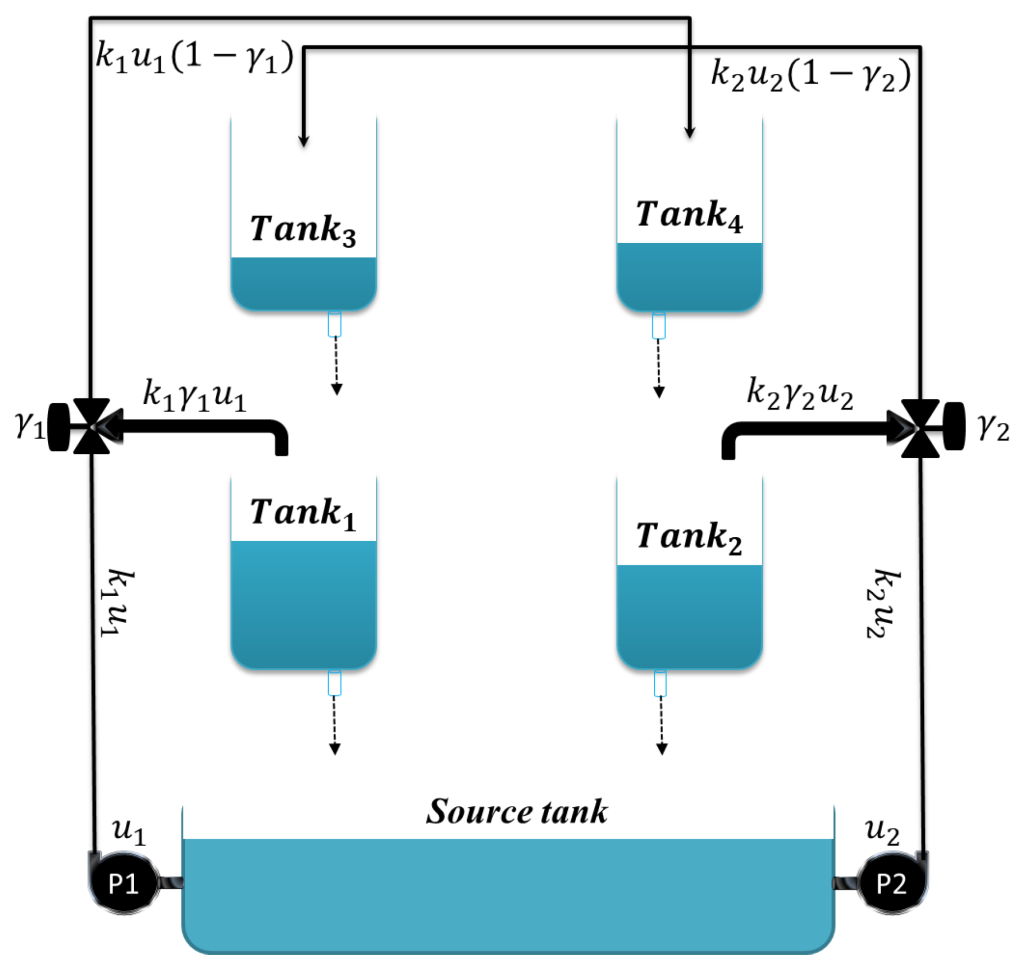

Image Source: apmonitor.com

A typical liquid level control system consists of several key components, including:

Sensors: These devices detect the fluid level and provide input to the control system.

Actuators: They regulate the flow of liquid in or out of the container, based on the control system’s instructions.

Control Panel: It serves as the central processing unit, where data from sensors is analyzed, and control signals are generated.

Communication Interface: This allows the control system to interact with operators or other external devices.

3. The Importance of Liquid Level Control: ⚙️

Image Source: mdpi.com

Accurate and efficient management of fluid levels is crucial for several reasons:

Preventing Overflow or Underflow: A well-functioning control system ensures that the fluid level remains within the desired range, minimizing the risk of overflow or underflow.

Optimizing Production Processes: Maintaining precise fluid levels is essential for achieving consistent product quality and maximizing production efficiency.

Ensuring Safety: In industries dealing with hazardous substances, proper liquid level control helps prevent accidents and potential harm to personnel and the environment.

4. Types of Liquid Level Control Systems: 🔄

Image Source: cwc.com.au

There are various approaches to liquid level control, depending on the application and requirements. Some common types include:

Float Switches: These simple devices use a float attached to a lever to activate or deactivate a switch when the liquid level reaches a certain threshold.

Ultrasonic Level Sensors: They utilize sound waves to measure the distance between the sensor and the liquid surface, providing highly accurate readings.

Pressure Transmitters: By measuring the pressure exerted by the liquid column, these devices can determine the fluid level in closed systems.

5. Applications of Liquid Level Control Systems: 💡

Liquid level control systems find extensive use across various industries:

Water and Wastewater Management: These systems help regulate water levels in reservoirs, tanks, and treatment plants, ensuring a continuous supply and preventing overflow or inadequate storage.

Chemical Processing: Precise control of liquid levels is critical in maintaining the desired concentration and ensuring the efficiency of chemical reactions and mixing processes.

Food and Beverage Production: Liquid level control systems are employed in the production of beverages, ensuring accurate filling and consistent product quality.

6. Challenges in Liquid Level Control: 🌊

Although liquid level control systems offer numerous benefits, they are not without challenges:

Environmental Factors: Changes in temperature, pressure, or humidity can affect the accuracy of sensor measurements, requiring additional calibration and compensation.

Fluid Properties: Liquids with varying viscosities, densities, or conductivities may pose challenges in terms of accurate level detection and control.

Maintenance and Calibration: Regular maintenance and calibration of sensors and actuators are essential to ensure reliable and accurate operation.

7. Future Developments in Liquid Level Control: 🔮

The field of liquid level control is continuously evolving, driven by advancements in technology and industry requirements. Some areas of development include:

Wireless Communication: Integration of wireless communication technologies allows for remote monitoring and control of liquid levels.

Artificial Intelligence: AI algorithms can enhance the accuracy and responsiveness of liquid level control systems, adapting to changing conditions.

Internet of Things (IoT): IoT-enabled sensors and devices enable real-time data collection and analysis, facilitating predictive maintenance and optimization of liquid level control.

Conclusion

In conclusion, liquid level control systems play a pivotal role in ensuring the efficient management of fluid levels across various industries. By maintaining precise control, these systems prevent overflow, optimize production processes, and enhance safety. While challenges exist, advancements in technology continue to drive the development of more intelligent and adaptable liquid level control systems. Now that you have a better understanding of this vital technology, consider implementing a liquid level control system in your operations to reap its numerous benefits. Cheers to effective liquid level management!

Disclaimer: The information presented in this article is for informational purposes only and should not be considered as professional advice. Please consult with industry experts for specific guidance tailored to your unique requirements.

This post topic: Liquid