Discover The Power Of The Square D Liquid Level Switch: Enhance Your Operations With Precision And Efficiency!

Square D Liquid Level Switch: An Essential Component for Industrial Applications

Introduction

Dear Readers,

Welcome to our informative article on the Square D Liquid Level Switch, an indispensable device in various industrial applications. In this article, we will delve into the details of this innovative switch, its functionality, advantages, disadvantages, and its impact on industrial processes. So, let’s dive right in!

3 Picture Gallery: Discover The Power Of The Square D Liquid Level Switch: Enhance Your Operations With Precision And Efficiency!

Table of Contents:

Overview of Square D Liquid Level Switch

What is a Square D Liquid Level Switch?

Who Uses Square D Liquid Level Switches?

When is a Square D Liquid Level Switch Required?

Where Can Square D Liquid Level Switches be Installed?

Why Choose a Square D Liquid Level Switch?

How Does a Square D Liquid Level Switch Work?

Advantages and Disadvantages of Square D Liquid Level Switches

Frequently Asked Questions (FAQs)

Conclusion

Final Remarks

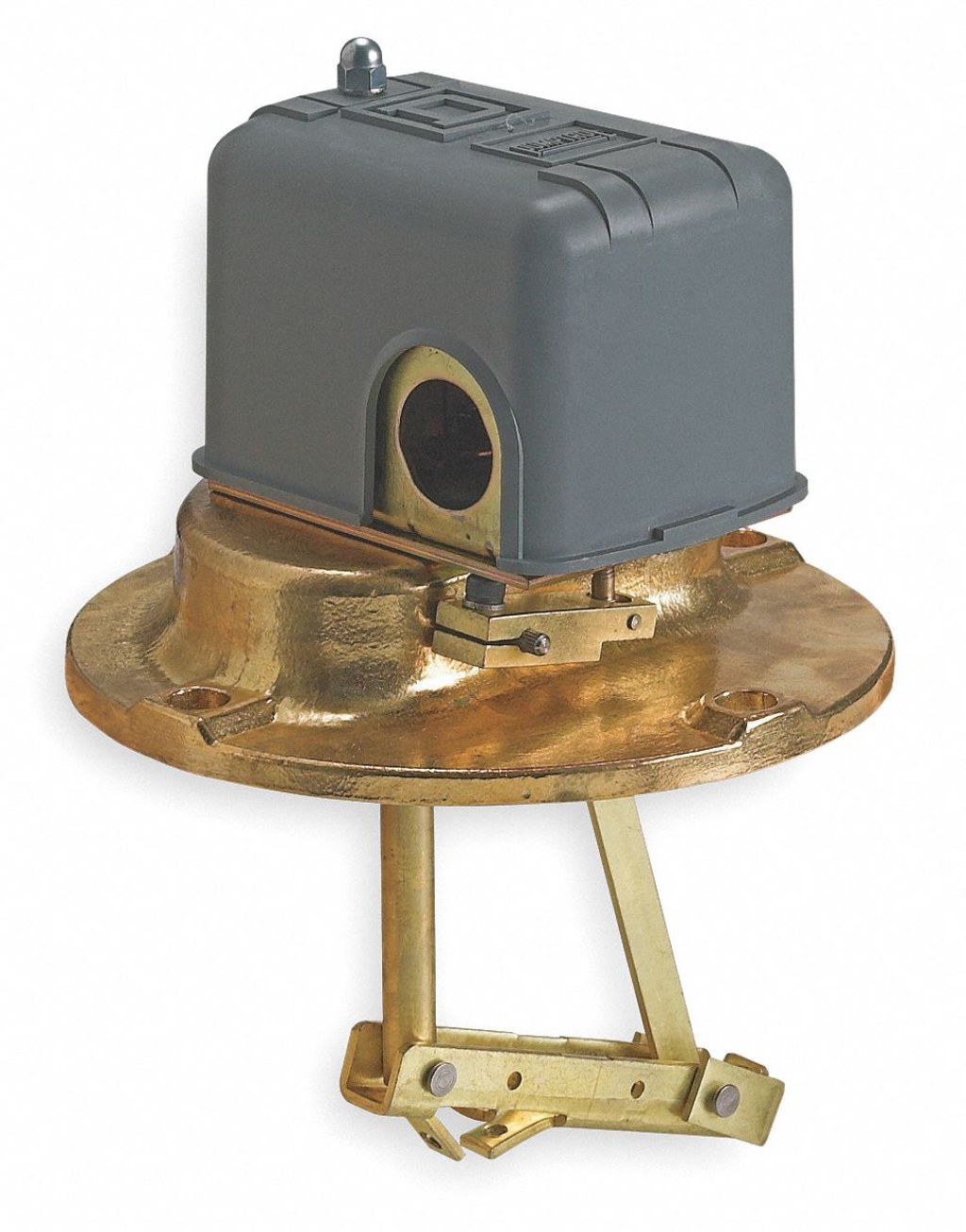

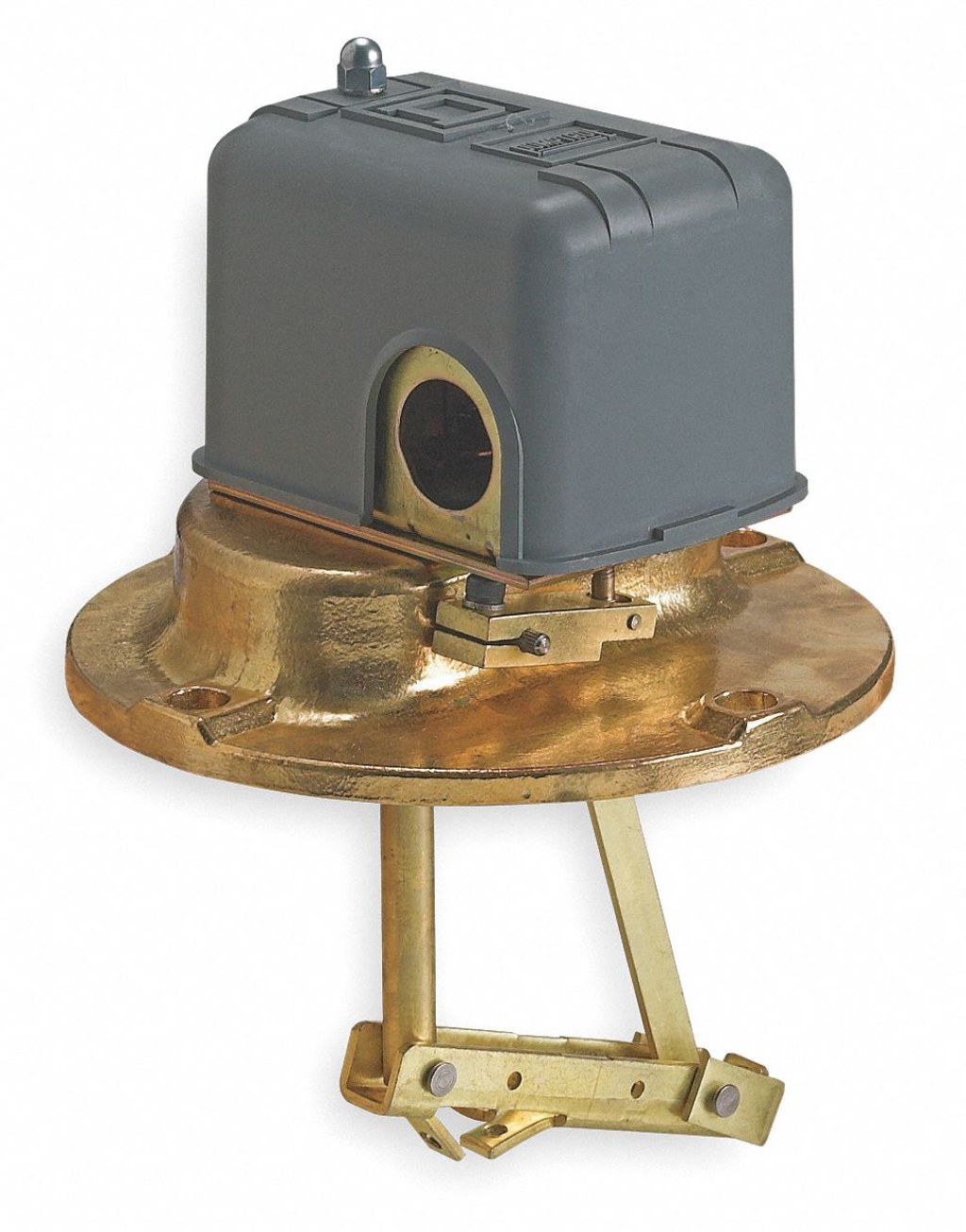

Image Source: grainger.com

Overview of Square D Liquid Level Switch

The Square D Liquid Level Switch is a state-of-the-art device designed to monitor and control liquid levels in tanks, reservoirs, and other containers. It operates based on the principles of conductivity and is widely used in industries such as water treatment, food and beverage, chemical, and oil and gas.

With its advanced technology and reliable performance, the Square D Liquid Level Switch ensures efficient operation and prevents overflow or dry running, which can lead to equipment damage and costly downtime.

What is a Square D Liquid Level Switch?

The Square D Liquid Level Switch is a precision instrument that detects changes in liquid levels and triggers the appropriate response to maintain optimal levels. It consists of a probe made from high-quality materials and a control unit with cutting-edge electronics. The probe is immersed in the liquid, and when the liquid reaches a certain level, the switch activates the control unit, which can initiate alarms, pumps, valves, or other actions depending on the application.

Who Uses Square D Liquid Level Switches?

Image Source: media-amazon.com

Square D Liquid Level Switches are widely used by industries that rely on accurate and reliable liquid level monitoring. This includes water treatment plants, manufacturing facilities, chemical plants, oil refineries, food and beverage production units, and agricultural operations. Any industry that requires precise control over liquid levels can benefit from the versatility and functionality of these switches.

When is a Square D Liquid Level Switch Required?

A Square D Liquid Level Switch is essential in situations where maintaining proper liquid levels is critical for operational efficiency, safety, and equipment protection. It is required in applications involving tanks, reservoirs, sumps, wells, and other liquid storage or containment systems. The switch ensures that the liquid levels are within the desired range and prevents potential issues such as overflow, leakage, or dry running.

Where Can Square D Liquid Level Switches be Installed?

Square D Liquid Level Switches can be installed in a wide range of environments, including indoor and outdoor settings. They can be used in tanks of various sizes, pipelines, channels, and even wastewater treatment plants. The switches are designed to withstand harsh conditions, temperature variations, and corrosive substances, making them suitable for diverse industrial applications.

Why Choose a Square D Liquid Level Switch?

There are several reasons why the Square D Liquid Level Switch is the preferred choice for many industries. Firstly, it offers high accuracy and reliability, ensuring precise liquid level monitoring and control. Secondly, it is easy to install and operate, saving time and effort during setup. Additionally, the switch is known for its durability and long lifespan, making it a cost-effective solution in the long run.

How Does a Square D Liquid Level Switch Work?

Image Source: media-amazon.com

The Square D Liquid Level Switch operates based on the conductivity principle. When the liquid level reaches the probe, which is connected to the control unit, it completes an electrical circuit. This completion of the circuit triggers the switch, activating the desired response, such as starting a pump or closing a valve. The switch can be programmed to respond differently based on the specific requirements of the application.

Advantages and Disadvantages of Square D Liquid Level Switches

Advantages:

Accurate and reliable liquid level monitoring

Easy installation and operation

Durable construction for long-term use

Wide range of applications

Prevents equipment damage and downtime

Disadvantages:

Initial investment cost

Requires periodic maintenance

May be affected by certain environmental factors

Frequently Asked Questions (FAQs)

Q1: Can a Square D Liquid Level Switch be used for hazardous liquids?

A: Yes, Square D Liquid Level Switches can be customized to handle hazardous liquids. They can be equipped with explosion-proof enclosures and special materials to ensure safe operation in such environments.

Q2: Can the switch be integrated with existing control systems?

A: Absolutely! Square D Liquid Level Switches can be easily integrated with existing control systems using standard communication protocols. This allows for seamless integration and improved automation.

Q3: How often should the switch be calibrated?

A: It is recommended to calibrate the switch periodically, depending on the application and environmental conditions. Typically, calibration is performed annually, but it may vary in specific cases.

Q4: Can the switch handle high-pressure applications?

A: Yes, Square D Liquid Level Switches are available in different models and configurations to handle high-pressure applications. These switches are designed to withstand the pressure and maintain accurate liquid level monitoring.

Q5: Can the switch be used for both liquid and solid materials?

A: No, Square D Liquid Level Switches are specifically designed for liquid level monitoring. For solid materials, alternative level switches such as capacitance or ultrasonic switches are more suitable.

Conclusion

In conclusion, the Square D Liquid Level Switch is an essential component in industrial applications that require precise liquid level monitoring and control. With its advanced technology, reliability, and versatility, it offers numerous benefits to various industries, ensuring efficient operations and preventing potential hazards. Whether it is for water treatment, chemical processing, or any other liquid-based process, the Square D Liquid Level Switch is a reliable choice for maintaining optimal liquid levels.

Final Remarks

Dear Readers,

We hope this article has provided you with valuable insights into the Square D Liquid Level Switch and its significance in industrial settings. It is crucial to choose the right liquid level switch for your specific application to ensure smooth operations and maximize productivity. Remember to consider factors such as accuracy, durability, and compatibility with your existing systems when making your selection. If you have any further questions or need assistance, feel free to reach out to our experts. Happy monitoring!

This post topic: Liquid